Hot Air Laboratory Oven

Hot Air Laboratory Oven Specification

- Technology

- Hot Air Circulation

- Machine Type

- Bench Top / Floor Mount

- Features

- Uniform Heat Distribution, Energy Efficient, Safety Lock, Over Temperature Protection

- Power Source

- Electric

- Control System

- Digital Temperature Controller with PID

- Accessories Type

- Adjustable Shelves, Timer, Safety Thermostat

- Accuracy

- 1C

- Operating Pressure

- Atmospheric

- Surface Treatment

- Powder Coated

- Type

- Laboratory Oven

- Material

- Mild Steel (MS) / Stainless Steel (SS)

- Function

- Drying, Sterilization, Baking, and Curing

- Application

- Laboratories, Research Centers, Industrial Testing

- Voltage

- 220 V / 230 V, 50 Hz

Hot Air Laboratory Oven Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Hot Air Laboratory Oven

Blessed by a team of extremely talented professionals, we are engaged in manufacturing and supplying a technically advanced range of Hot Air Laboratory Oven. Inner chamber made of SS, and outer made by power coated MS, these ovens are regarded for their easy installation, low maintenance and energy efficiency. Our Hot Air Laboratory Oven helps in attaining the uniform temperatures for various laboratory processes such as annealing, die-bond curing, drying and Polyimide baking. Furthermore, we are offering these ovens at a reasonable price.

Specifications:

- Gap between the walls filled with glass wool insulation

- Heating element is made of High grade chrome plated Nichrome Wire

- Temp. Range 50Deg.C to 250Deg.C and Accuracy +/-2Deg.C

- Air Ventilation is provided on the top of the unit to vent the hot gases/fumes

- 12" x 12" x 12"

- 14" x 14" x 14"

- 18" x 18" x 18"

- 18" x 18" x 24"

- 24" x 24" x 24"

- 18" x 24" x 36"

- 24" x 24" x 36"

Reliable Performance Across Laboratory Applications

Our Hot Air Oven excels in delivering precise and uniform temperature control for diverse laboratory and industrial tasks. It supports essential functions like sterilization, drying, and curing using advanced hot air circulation technology. The adjustable shelves, safety thermostat, and digital timer increase operational convenience, making it ideal for applications in research, quality control laboratories, and industrial testing environments.

Superior Construction for Long-term Durability

This oven combines a stainless steel inner chamber with a robust powder-coated mild steel exterior, both designed for long life and minimal maintenance. Double-walled doors with high-grade gaskets and 75 mm glass wool insulation keep operational efficiency high and heat loss low, ensuring reliable outcomes even during continuous operation.

FAQs of Hot Air Laboratory Oven:

Q: How does the hot air laboratory oven ensure uniform heat distribution?

A: The oven uses a motorized blower system that circulates hot air evenly throughout the stainless steel chamber. This, combined with nickel chrome plated heating elements and thick glass wool insulation, guarantees consistent temperatures for precise drying, sterilization, and baking.Q: What are the key applications of this laboratory oven?

A: This oven is widely used for drying, sterilizing, baking, and curing tasks in laboratories, research centers, and industrial quality control departments. Its broad chamber volume and precise temperature control make it suitable for a wide range of material and sample types.Q: When should I use the adjustable shelves and how do they benefit laboratory work?

A: Adjustable shelves are ideal when you need to accommodate samples or items of varying sizes. They maximize the chamber space, improve airflow around samples, and help maintain uniform temperature exposure for efficient processing in one batch.Q: Where is this hot air laboratory oven best installed in a laboratory setup?

A: You can choose between bench top or floor mount models, depending on your workspace and sample volume requirements. It is important to place the oven in a well-ventilated area, away from sources of moisture or direct sunlight, for optimal performance.Q: What process does the digital temperature controller with PID follow to maintain accuracy?

A: The PID (Proportional-Integral-Derivative) controller continuously monitors and regulates the internal temperature by comparing real-time chamber conditions with the set point. It automatically adjusts the heating elements power to ensure accuracy within 1C, reducing temperature overshoot or fluctuation.Q: How do I ensure safety during prolonged oven operation?

A: For safety, the oven is equipped with an over-temperature protection system, a safety thermostat, and a secure locking mechanism on the double-walled door. Always monitor the digital display and activate the timer and thermostat features for worry-free, safe operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Roll Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Operating Pressure : Standard Atmospheric Pressure

Surface Treatment : Paint Coated

Accuracy : High Precision

Accessories Type : Wear Resistant Rollers

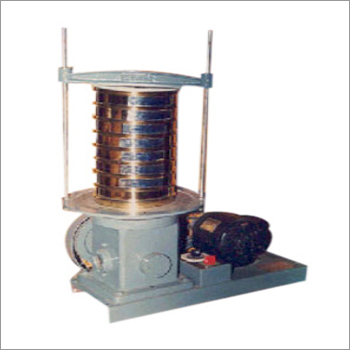

Sieve Shaker

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Operating Pressure : Atmospheric

Surface Treatment : Powder Coated

Accuracy : High Precision with Consistent Results

Accessories Type : Sieve Stack, Lid, Receiver

Muffle Furnace

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Operating Pressure : Atmospheric

Surface Treatment : Powder Coated

Accuracy : 2C

Accessories Type : Crucible, Tongs, Tray

Computerized Universal Testing Machine

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Operating Pressure : Hydraulic, Up to 200 bar

Surface Treatment : Powder Coated

Accuracy : 1% of indicated load

Accessories Type : Grips, Extensometer, Compression Platens, Bending Attachments

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry