Melting Range Apparatus

Price 10000.00 INR/ Number

Melting Range Apparatus Specification

- Control Type

- Rotary knob (manual control)

- Temperature Resistance

- Up to 300C

- Accuracy

- 1C

- Glass Type

- Borosilicate Glass Capillaries

- Features

- Uniform heating, easy to operate, quick reach to set temperature, glass shield for observation

- Speed Range

- Manual adjustment

- Power Supply

- 230V, 50Hz

- Shape

- Rectangular

- Heating Capacity

- Ambient to 300C

- Type

- Melting Range Apparatus

- Dimension (L*W*H)

- 210 mm x 210 mm x 500 mm

- Equipment Type

- Lab Testing Instrument

- Equipment Materials

- Powder coated mild steel body, glass capillaries

- Power

- 60W

- Voltage

- 220V AC

- Material

- Stainless Steel, Glass, Mild Steel

- Capacity (Ltr)

- 500 ml bath

Melting Range Apparatus Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 4 Per Month

- Delivery Time

- 3-8 Week

About Melting Range Apparatus

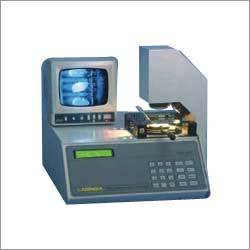

Melting Range Apparatus

Offering a precision engineered range of melting range apparatus and visual melting range apparatus with following features: This app. Consists of a cylindrical block of aluminum with a built in electrical heating element. The mounted Alum. Block illuminates from below by a lamp fixed in its housing. The aluminium block accept three capillary tubes and mercury thermometer. The temp. is controlled by rotary switch. The magnifying lens provided for viewing objects clear. Suitable for operation on 220 Volts AC circuits.

Melting Range Apparatus (MEPA)

- Advanced micro-controller based design.

- Accurate and precise detection of melting range.

- Temperature range : Ambient + 10oC to 300oC.

- Operating Modes : Standard Mode, USP Methods 1a and 1b.

- Storage of 20 methods and 15 results.

- GLP compliant reports.

- PC compatibility.

Accurate Melting Range Determination

Quickly and accurately determine the melting points of solid and powdered pharmaceutical samples using this purpose-built Melting Range Apparatus. The equipments liquid paraffin oil bath ensures uniform heat distribution, while its rotary knob allows precise manual adjustments. Maintaining an accuracy of 1C, it is suited for applications requiring stringent temperature control, making it ideal for laboratories, research centers, and quality control departments.

Robust Construction and Safety Features

Engineered with powder-coated mild steel and stainless steel components, the apparatus withstands rigorous laboratory environments. A built-in fuse enhances user safety by guarding against power surges, while the stable rubber feet prevent accidental tipping. The apparatuss borosilicate glass capillaries support high-temperature exposure, allowing for repeated and safe sample observations through the integrated glass shield.

FAQs of Melting Range Apparatus:

Q: How does the Melting Range Apparatus operate for sample testing?

A: The apparatus heats samples in borosilicate glass capillaries inserted into a bath filled with liquid paraffin oil. Temperature rise is manually controlled using a rotary knob, and users observe the melting process through a protective glass shield. Multiple capillaries can be tested simultaneously to streamline analysis.Q: What are the benefits of using this melting range apparatus in laboratories?

A: This instrument combines accurate temperature measurement (1C), quick and uniform heating, and safety features like fuse protection. Its robust material construction and stable rubber feet make it reliable for continuous use, while multiple capillary slots increase throughput and convenience.Q: When should the liquid paraffin oil in the bath be checked or replaced?

A: Regularly inspect the paraffin oil for contaminants or discoloration, especially after extensive usage or numerous sample runs. Replace the oil if it becomes cloudy or degraded to ensure consistent thermal conductivity and accurate melting point determination.Q: Where is this melting range apparatus typically used?

A: This equipment is commonly utilized in pharmaceutical laboratories, academic research institutions, and quality assurance departments involved in analyzing the melting characteristics of powdered and solid samples.Q: What materials ensure the durability and effectiveness of the apparatus?

A: The apparatus features a powder-coated mild steel body for durability, stainless steel components for corrosion resistance, and borosilicate glass capillaries for high temperature and chemical resilience, all contributing to long-lasting operational efficiency.Q: How does the manual rotary knob control influence the testing process?

A: The rotary knob enables users to precisely and gradually adjust the temperature, affording better control over the heating rate and minimizing the risk of overshooting the target range, which is essential for accurate melting point determination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Testing Instrument Category

Automatic Titrators (TITRA)

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Automatic Titrators

Power : 25W

Capacity (Ltr) : Up to 1 L

Voltage : 230V AC 10%, 50/60 Hz

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry